Grinding discs are important tools in industrial settings used for the cutting, grinding and finishing of materials including metal, stone and concrete. In their broad usage, improper handling of grinding discs can cause security hazards, damage to machinery, and unsatisfactory results. Grinding discs are among the most commonly used tools in various industries, so it is critical to adhere to best practices and safety protocols to operate them safely.

Note: The largest stock of NKK grinding and cutting discs for all types of work is now available in our warehouse. If you are looking for high-quality grinding or cutting discs, feel free to explore and shop on our website: https://www.udo.co.th/category_product/ใบตัดใบเจียร.

The Basics of a Grinding Disc

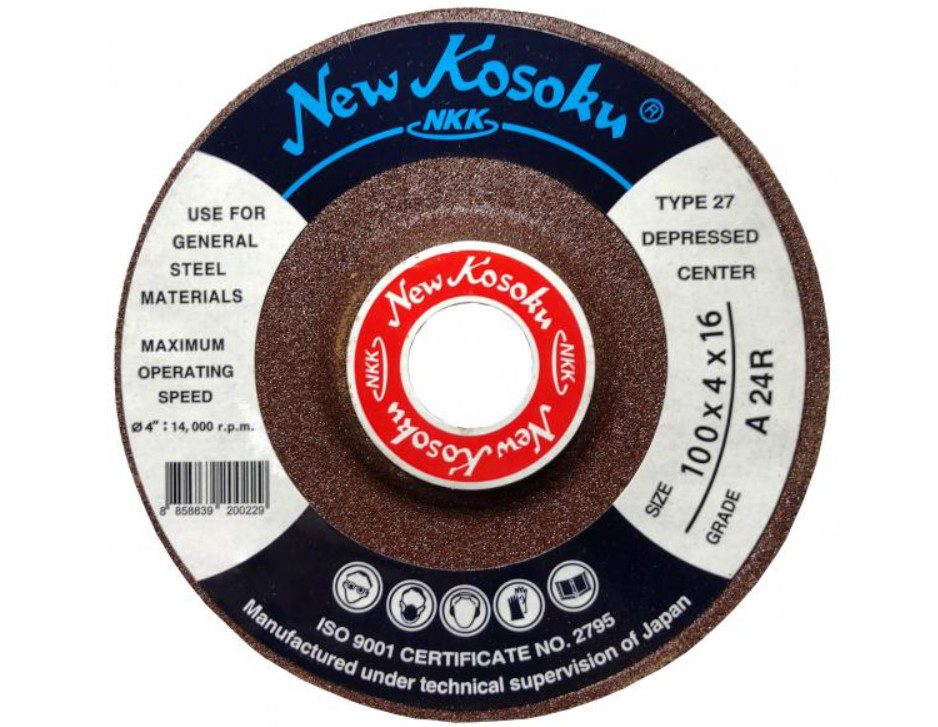

A grinding disc, also known as a grinding wheel or grinding plate in some regions, is a type of circular, abrasive tool designed to be mounted onto power grinders that utilize them for industrial applications such as metalworking, manufacturing, and construction. They are available in many types, home in on particular uses, such as cutting, grinding or polishing. But the high rotation speed and abrasive character of grinding discs can make them dangerous if used carelessly.

Many risks have to be mitigated, but operators need to know which type of tool they are using, and most importantly, it needs to be appropriate for the task. For example, cutting discs are thinner and used for slicing through materials, whereas grinding discs are thicker and used for material removal.

Best Practices for Safe Grinding Disc Use

1. Inspect Before Use

Inspection of a grinding disc before its use: Look for signs of damage, like cracks, chips or uneven wear. It is common for discs to develop a crack, but a small crack can still cause disc shattering while the disc is in operation, presenting a very serious safety risk. Note: Always check that the grinding disc is suitable for the grinder you are using, including size, RPM rating, and the type of material.

2. Wear Personal Protective Equipment (PPE)

Grinding discs, like all cutting tools, require safety equipment. Provide protective eyewear, gloves, hearing protection, and face shield to operators. Long sleeves, as well as “clothes made of flame-resistant material” are also recommended to protect from flying debris and sparks, the guideline states.

3. Secure the Workpiece

Keep the item you are working on clamped down or held firmly. An unsteady workpiece may cause the grinding disc to slip, resulting in death or injury or damage to the material.

4. Move at the Right Speed

Each grinding disc has designated operating limits according to its speed — RPM, displayed on the hosting disc. Over-speeding will increase the danger of disc damage, so never exceed this limit. Check the grinder’s settings regularly to be sure that it is configured to the specs of the disc.

5. Position Your Body Correctly

Be sure to always grip the grinder firmly and hold it steady. Hold grinding disc at specified angle — generally 15 to 30 degrees — to ensure smooth performance and minimize the chances of kickback. Never scrub too hard, as this might lead to the disc overheating and thus losing structural integrity.

6. Avoid Using Damaged Tools

Do not operate a grinder with missing or broken parts, worn flanges, loose bolts or a defective guard. The guard is very important because it protects the operator from debris and a potential disc failure. Always make sure the grinder is working well before beginning any job.

7. Regular Maintenance

Always ensure to maintain the grinding discs and tools regularly for safety and efficiency. Keep grinding discs dry and cool to avoid warping or moisture damage. Also, do regular maintenance of cleaning the grinder to remove debris, which could affect the performance.

Common Mistakes to Avoid

Using the Incorrect Disc: All grinding discs have their own jobs to do. When using a cutting disc for grinding or vice versa, poor results will occur, and at the same time, safety hazards will be greatly increased.

Safety Checks Out: It is easy to miss. Not seeing that the disc is replaced correctly, or the grinding tool itself is functional.

Storage Mistakes: Storing grinding discs in damp or very cold roads can damage them, rendering them unsafe for use.

Conclusion

It is vital to guarantee safe operation of a grinding disc when working in this area to reduce the possibility of accidents and ensure maximum efficiency. Inspecting discs before use, following safe operating procedures, and ensuring equipment is in good working order allows operators to mitigate risk associated with grinding operations. Never forget, safety is a two-way street so when you put time into training and awareness you are not only protecting the workers but also increasing productivity and the life span of the grinding tools. Remember, safety is key in getting the best from your grinding disc operations.